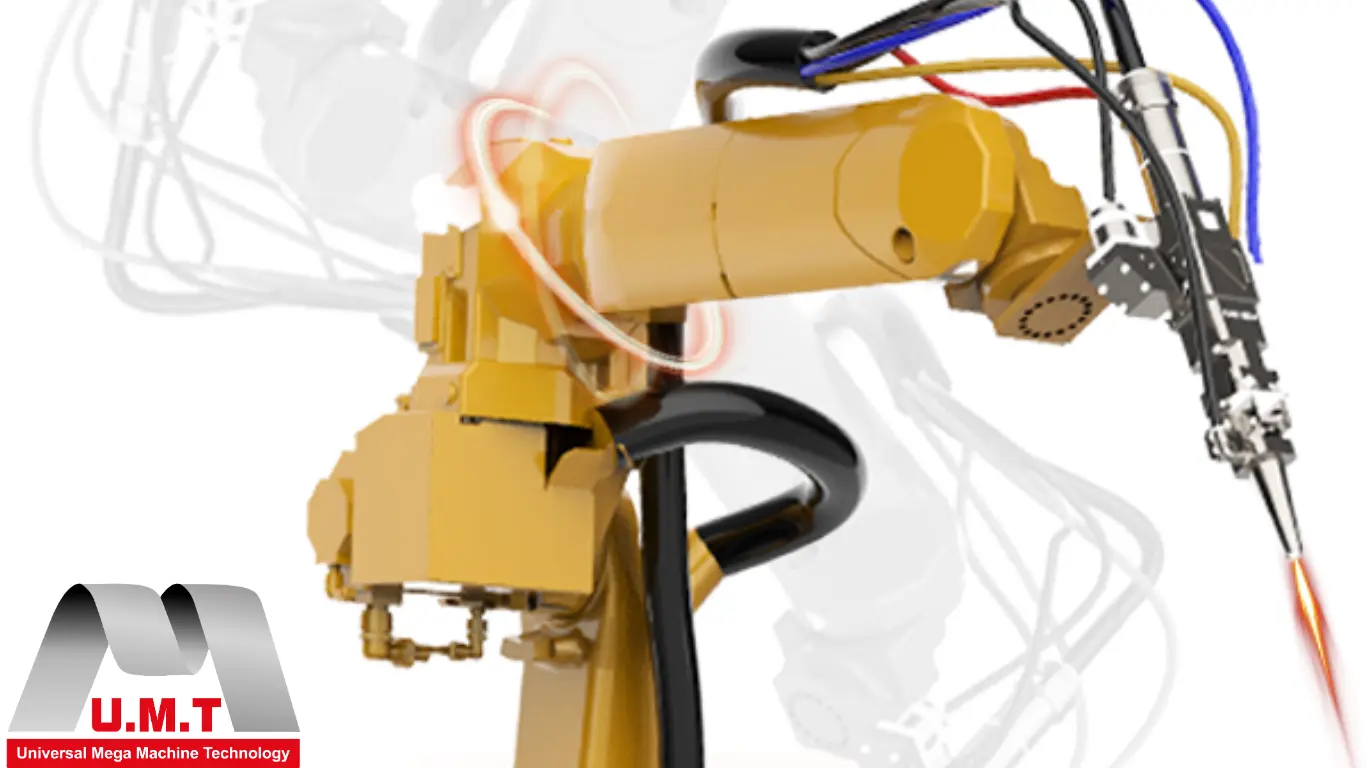

Best Robotic Welding Machines in Dubai in this technology has revolutionized the manufacturing and construction sectors worldwide, including in Dubai, where rapid industrial growth demands advanced automation solutions. The adoption of robotic welding machines in Dubai is instrumental in enhancing production efficiency, precision, and safety across various industries such as automotive, aerospace, shipbuilding, and infrastructure development. This essay explores the best robotic welding machines available in Dubai, highlighting their features, advantages, and how they meet the region’s industrial needs.

Overview of Robotic Welding Technology

Robotic welding machines consist of programmable robotic arms equipped with welding tools that perform precise welding tasks automatically. Unlike manual welding, robotic welding offers consistent quality, higher throughput, and reduced labor costs. These machines use advanced sensors, artificial intelligence, and computer numerical control (CNC) systems to execute complex welds with minimal human intervention.

Industrial Landscape of Dubai and the Need for Robotic Welding

Dubai’s strategic location as a global trade hub and its focus on becoming a smart city have accelerated industrial automation. The construction boom, expansion of manufacturing bases, and increasing demand for high-quality metal fabrication make robotic welding indispensable. Compared to traditional welding, robotic systems reduce errors and rework, enabling companies to meet stringent quality standards and deadlines.

Top Robotic Welding Machines in Dubai

Several international and regional manufacturers provide robotic welding machines in Dubai, tailored to diverse industrial requirements. The best machines combine state-of-the-art technology with local support services.

- FANUC Robotic Welding Systems

FANUC is a global leader in industrial robotics, known for reliability and advanced capabilities. Their robotic welding systems in Dubai are widely used due to:

- High Precision: Capable of complex fillet and butt welds.

- Speed: Enables high-speed arc welding minimizing cycle times.

- Flexibility: Modular designs support various welding processes (MIG, TIG, spot welding).

- Ease of Integration: Compatible with existing production lines and software.

- Local Support: FANUC has an established presence in Dubai, providing maintenance and training.

- ABB Robotics Welding Solutions

ABB offers a broad portfolio of robotic welding machines suitable for automotive, aerospace, and heavy machinery industries. Key features include:

- Advanced Sensors: Real-time monitoring for weld quality.

- Collaborative Robots: Enhances safety working alongside human operators.

- Adaptive Control: Automatically adjusts welding parameters to material variations.

- Energy Efficiency: Optimized power consumption reducing operational costs.

- Extensive Service Network: ABB Dubai provides installation, repair, and consultation.

- KUKA Robotic Welders

KUKA’s robotic welders are popular in Dubai for their robustness and versatility. Attributes that make KUKA standout include:

- High Payload Capacity: Suitable for heavy-duty industrial applications.

- User-friendly Programming: Simplifies task setup and customization.

- Smart Welding Functions: Integrated data analytics for process optimization.

- Global and Regional Support: KUKA representatives in Dubai ensure swift technical assistance.

- Panasonic Robotic Welding Systems

Panasonic provides precision robotic welders equipped with intelligent welding controls. Features attractive to Dubai businesses include:

- Quality Assurance: Consistent weld bead formation with minimal spatter.

- Process Versatility: Supports MIG, TIG, and Pulse welding modes.

- Compact Design: Ideal for space-constrained production environments common in Dubai industrial zones.

- Training & Support: Panasonic offers comprehensive local training programs.

Advantages of Using Robotic Welding Machines in Dubai

- Improved Productivity: High-speed welding cycles increase throughput.

- Enhanced Quality: Precision welding decreases defects and material waste.

- Cost Efficiency: Automation reduces the dependency on skilled labor.

- Safety: Reduces worker exposure to hazardous fumes and intense light.

- Scalability: Easily adaptable to different production volumes and product types.

Challenges and Considerations

While robotic welding machines offer numerous benefits, Dubai-based companies must consider:

- Initial Capital Expenditure: High upfront costs for purchase and installation.

- Skilled Workforce: Requirement for trained personnel to program and maintain robots.

- Integration Complexity: Ensuring seamless integration with existing systems.

- Customization Needs: Machines must be tailored for specific applications.

Future Trends in Robotic Welding in Dubai

Emerging technologies such as artificial intelligence, machine learning, and cloud connectivity are making robotic welding smarter and more autonomous. Dubai’s commitment to innovation and smart manufacturing paves the way for adoption of Industry 4.0-enabled robotic welding systems that can self-optimize and perform predictive maintenance.

Conclusion for Best Robotic Welding Machines in Dubai

Dubai’s dynamic industrial environment demands high-quality, efficient, and reliable welding solutions, positioning robotic welding machines as essential tools. Among the best options in Dubai are offerings from FANUC, ABB, KUKA, and Panasonic—each bringing advanced features and localized support suited to the region’s unique challenges and opportunities. As industries continue to evolve, embracing cutting-edge robotic welding technology will be key to maintaining competitive advantage and achieving sustainable growth in Dubai’s manufacturing and construction sectors.