Robotic Press Brake Solutions

Discover how robotic integration can reshape your metalworking production.

Press brakes are essential machines for precision sheet metal bending—used across industries like automotive, construction, and heavy machinery. But bending doesn’t have to be manual anymore.

Imagine a press brake that doesn’t need an operator.

Now imagine every bend done with perfect accuracy, zero fatigue, and 24/7 repeatability.

By integrating an industrial robot with your CNC press brake, you eliminate human error, speed up your production line, and reduce labor costs—all while maintaining the highest quality standards.

Our robotic bending systems, powered by Estun’s advanced automation technology, are tailored to your exact needs. Whether you produce small parts or heavy-duty profiles, we’ll design a solution that fits.

Request more information

video Automatic production line

A six-axis robot with an 80 kg payload capacity, the ER80B provides high-speed operation with exceptional positioning accuracy (repeatability under 0.1 mm). It is designed to handle, position, and support metal sheets with precision—ideal for complex and multi-stage bending operations.

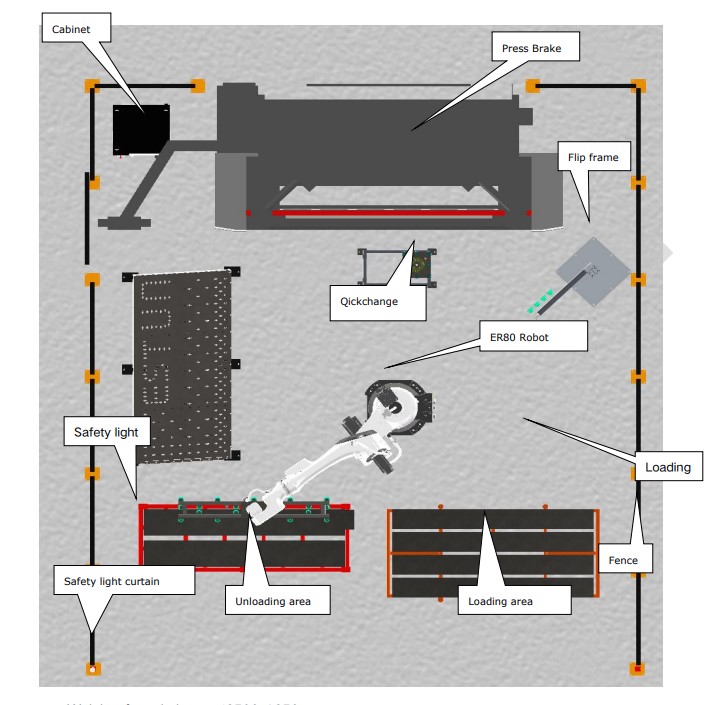

Robotic Bending Solution

Innovative Metal Bending with Estun ER80B Robot and CNC Press Brake Integration

In today’s competitive manufacturing landscape, precision, speed, and repeatability are key factors for success. Automating traditional processes such as bending enables manufacturers to increase efficiency, reduce operational costs, and maintain consistent product quality.

Estun ER80B Industrial Robot

System Components Estun ER80B Industrial Robot

Some of all our solutions

🗸 System Components

Estun ER80B Industrial Robot

A six-axis robot with an 80 kg payload capacity, the ER80B provides high-speed operation with exceptional positioning accuracy (repeatability under 0.1 mm). It is designed to handle, position, and support metal sheets with precision—ideal for complex and multi-stage bending operations.

🗸 CNC Press Brake

A state-of-the-art bending machine equipped with intelligent control systems and full support for CAD/CAM input (DXF/STEP). The press brake automatically calculates bending angles and forces and performs operations without human intervention.

How It Works

1. Metal sheets are loaded manually or via automatic feeding systems

2. The Estun ER80B robot picks up the sheet and positions it in front of the press brake

3. The CNC press brake performs the programmed bending operation

4. The robot repositions the part for additional bends or places it in the output station

5. The process is repeated continuously for high-volume, uninterrupted production

difference between hydraulic and electric Press Brake

|

electric press brake

|

hydraulic press brake

|

|---|---|

|

100% pure electric

|

do with oil

|

|

50% less energy

|

using very energy

|

|

35% faster than hydraulic

|

very slowly

|

|

High bending speed and less noise.

|

low bending speed and high noise.

|

|

Friendly user interface.

|

Old user interface.

|

Request more information

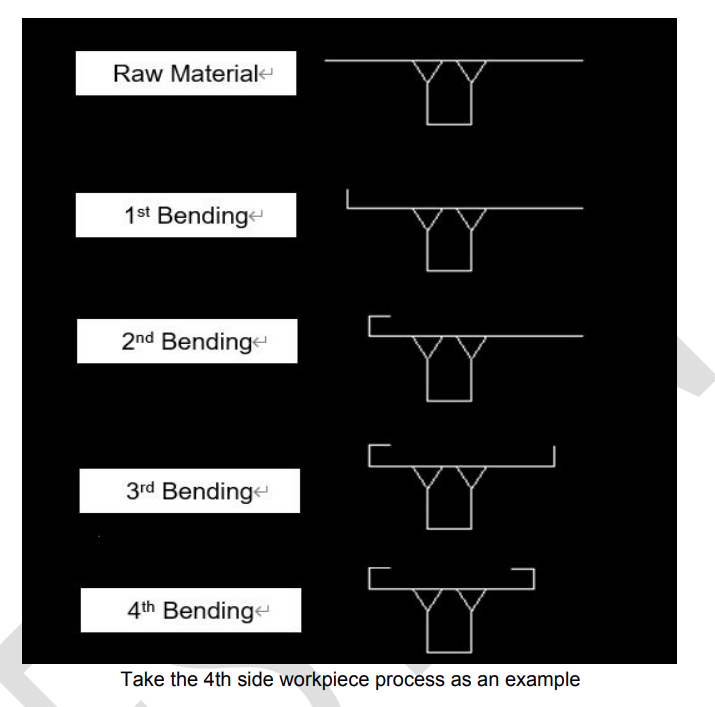

system introduction

production process

Request more information

Introduction to Press Brakes: A Versatile Tool for Metal Forming

A press brake is a manufacturing machine used to bend and shape sheet metal components. It is commonly used for processing and forming metal materials such as steel, aluminum, and stainless steel.

The operation of a press brake involves placing the sheet metal between two channels, and a press with high force applies pressure to bend the sheet metal. During this process, the sheet metal is positioned between the press and a die with the desired bending shape, and through the pressing force, it is bent into the desired shape.

Press brakes are used in various industries such as automotive manufacturing, construction, metal fabrication, and industrial component production. This machine has the capability to produce components with different shapes, and depending on the type of die and dimensions used, it can operate automatically or manually.

Using a press brake as a manufacturing process requires precision and high accuracy. Proper operation and maintenance of the machine can contribute to the precision and quality of the produced components.

Estun robot

Estun Robotics Estun Robotics Leading the IndustryEstun’s commitment to innovation has made it a top

Welding and Cutting Robot

Metal welding and cutting robot Introduction Overview Features Applications Software Introduction Robotic 3D Laser Cutting

panel benders

panel benders and Robotic System Panel bending machine with robot and set upThe panel bender is a