Effective solutions for diferent types of parts

Revolutionize Your Production with Mega Machine’s Robotic Solutions

Step into the future of manufacturing with Mega Machine’s advanced robotic solutions. Our robots are designed to automate processes, boost efficiency, and enhance precision, offering cost-effective and scalable solutions for various industries.

Why Choose Mega Machine’s Robotic Machines?

- Automation Excellence: Streamline operations and increase productivity with intelligent automation.

- Precision: Achieve top-quality output with unmatched accuracy.

- Cost Efficiency: Reduce operational costs by optimizing resources.

- Versatility: Our robots handle a wide range of tasks, from welding and assembly to material handling and packaging.

- Scalability: Easily scale production to meet growing demands.

Request more information

Robotic Solutions

Automatic Press Brake with Material Handling Robots

This fully automated press brake machine operates seamlessly 24/7, without the need for human intervention. The robot efficiently picks up and places metal sheets, ensuring smooth loading and unloading processes for continuous, precise production. Perfect for enhancing productivity and minimizing downtime.

Panel Bender with Robotic Integration

Our Panel Bender combined with advanced robotic technology automates the bending process with high precision and efficiency. The robot ensures accurate handling of metal panels, increasing production speed while maintaining quality. Perfect for high-volume operations that require consistent results.

Fiber Laser Metal Cutting Machine with Material Handling Robots

This advanced Fiber Laser Metal Cutting Machine is seamlessly integrated with robotic loading and unloading systems. The robot efficiently handles and places metal sheets, ensuring a smooth workflow with no human intervention. Perfect for high-precision cutting while optimizing production time and reducing manual labor.

welding and cutting robot

Our Robotic Welding Machine is designed to deliver precise, consistent welds with minimal downtime. Integrated with advanced robotic technology, it automates the welding process, handling heavy tasks like loading and unloading materials effortlessly. Additionally, our Cutting Robot complements this system by providing accurate and efficient material cutting, streamlining the workflow. Ideal for high-volume production, these machines ensure top-quality results while improving efficiency and reducing the need for human labor.

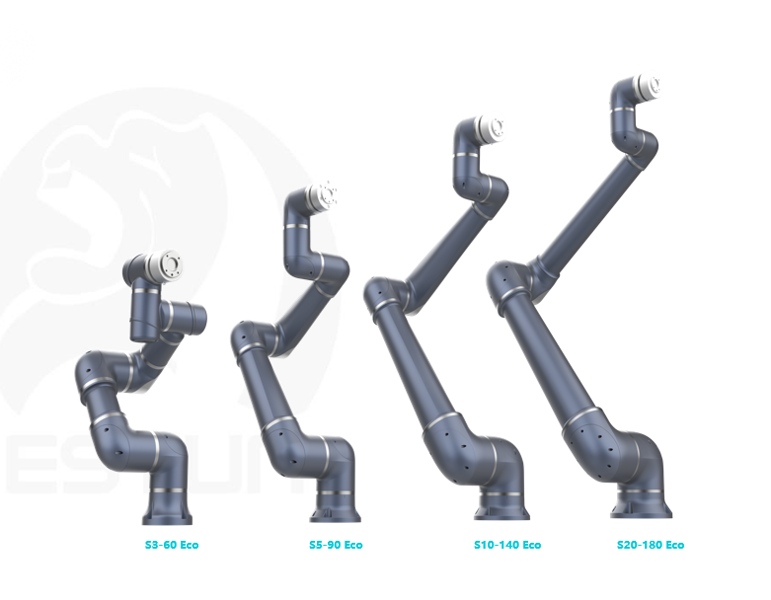

Collaboration Estun Robotic Solutions

Innovative Technology: From special robots for stamping and bending to high protection die-casting robots, ESTUN provides tailored solutions that elevate product quality and competitiveness. Comprehensive Solutions for the Entire Metalworking Process ESTUN offers end-to-end solutions, covering auto mated core production, parts handling, processing welding, die-casting, drilling, milling, plate bending, and subsequent processing.

As leaders in robotics

automation and Industry 4.0, we integrate digital technology and robotic products to deliver superior quality solutions.