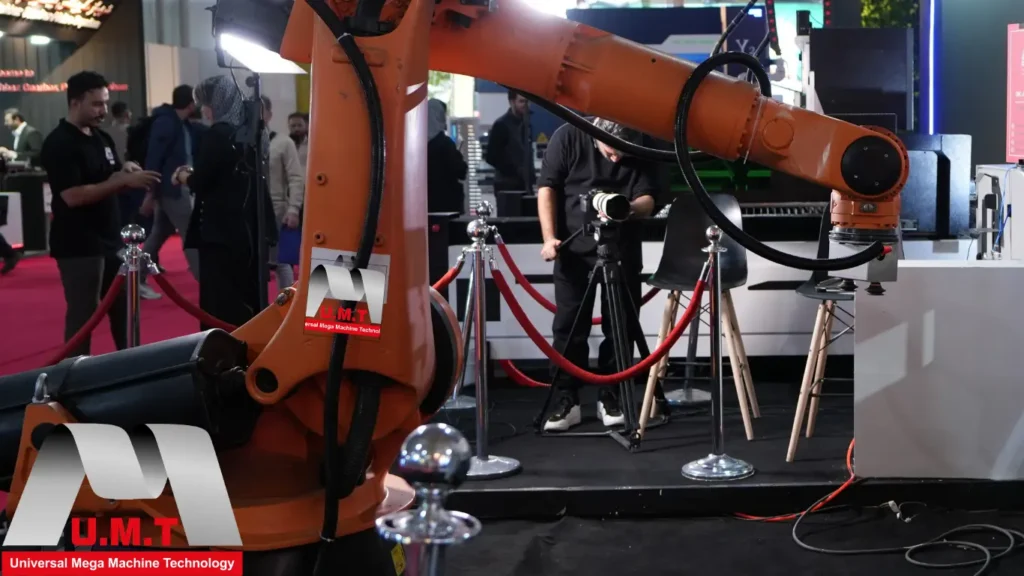

In the ever-evolving landscape of manufacturing technology, automation plays a critical role in improving efficiency, precision, and productivity. Among the myriad tools revolutionizing industrial processes, bending robots stand out as essential machines for shaping and fabricating metal parts. Mega Machine, an innovative leader in robotics and automation, has developed a state-of-the-art bending robot equipped with advanced features designed to meet the rigorous demands of modern manufacturing. This essay offers a complete introduction to the four main features of Mega Machine’s bending robot, highlighting how each contributes to making it an indispensable asset in fabrication workflows.

Introduction to the 4 Features of Mega Machine’s Bending Robot

In the future we want to tell you about all things to you know about Bending Robot :

Feature 1: High-Precision Bending Mechanism

The hallmark of Mega Machine’s bending robot is its high-precision bending mechanism, which ensures consistently accurate and repeatable bends on metal sheets and components. The robot integrates advanced servo motors and finely tuned hydraulic systems that provide precise control over bending angles and forces. This feature is supported by sophisticated sensors and feedback loops that monitor the bending process in real time, compensating for variables such as material thickness and elasticity. By maintaining exact tolerances, the bending robot minimizes waste and ensures a high-quality finish, reducing the need for subsequent manual adjustments or rework.

Feature 2: Versatile Material Compatibility

Mega Machine’s bending robot is designed to be versatile, effectively working with a wide range of metals including steel, aluminum, copper, and various alloys. This versatility is achieved through adjustable tooling and flexible programming that accommodate different material properties and thicknesses. Whether dealing with thin, delicate sheets or thicker, more rigid plates, the robot adapts its approach to optimize the bending process without compromising precision or risking damage to the material. This adaptability makes it well suited for industries such as automotive, aerospace, construction, and appliance manufacturing, where diverse materials and specifications are common.

Feature 3: Intelligent Automation and Programmability

A standout feature of Mega Machine’s bending robot is its intelligent automation capabilities, driven by an advanced programmable controller and integrated software suite. Operators can program complex bending sequences and parameters through an intuitive interface, allowing for quick setup and modification of jobs. The robot employs machine learning algorithms that analyze previous bending operations to optimize cycle times and reduce material stress. Additionally, the system can simulate bending processes digitally before execution, identifying potential issues and ensuring the final product meets design specifications. This intelligent programmability enhances operational efficiency and empowers manufacturers to maintain high throughput without sacrificing quality.

Feature 4: Robust Safety and User-Friendly Design

Safety and usability are paramount considerations in the design of Mega Machine’s bending robot. The machine features multiple layers of safety mechanisms including emergency stop buttons, safety light curtains, and protective guarding to prevent accidents during operation. Furthermore, the robot’s user-friendly design incorporates ergonomic loading and unloading stations, clear visual displays, and straightforward maintenance access points. Training time for operators is minimized thanks to intuitive controls and comprehensive diagnostic tools that quickly identify and resolve any operational issues. The combination of safety and usability ensures that the robot not only performs at a high level but does so in a manner that protects workers and maximizes uptime.

Conclusion for a complete introduction to the 4 features of Mega Machine’s bending robot

Mega Machine’s bending robot exemplifies the cutting edge of automation technology in metal fabrication. Through its high-precision bending mechanism, versatile material compatibility, intelligent automation and programmability, and robust safety and user-friendly design, the robot delivers unparalleled performance and efficiency. These four features collectively enhance productivity, reduce operational costs, and improve product quality across a broad range of industrial applications. As manufacturers continue to seek smarter and more reliable automation solutions, Mega Machine’s bending robot stands out as a comprehensive tool engineered to meet the challenges of modern manufacturing environments.

FOR MORE INFORMATION ABOUT ANY MACHINES IN MEGA MACHINE CLICK HERE !!!