Reviewing 1 of the most important features of any device

The Accurl Press Brake Price, like any industrial machinery, is influenced by a multitude of factors. Understanding these elements is crucial for potential buyers to make informed decisions that align with their specific manufacturing needs and budget. While a precise price quote requires direct consultation with Accurl or their distributors, we can explore the key aspects that determine the cost.

- Machine Specifications: The fundamental specifications of the press brake are primary drivers of price. These include:

- This refers to the maximum force the press brake can exert. Higher tonnage machines, capable of bending thicker and tougher materials, will generally be more expensive due to the more robust construction and powerful hydraulic systems required.

- Bending Length: The length of the working table dictates the maximum size of the workpiece that can be processed. Longer bending lengths necessitate larger machine frames and components, leading to increased costs.

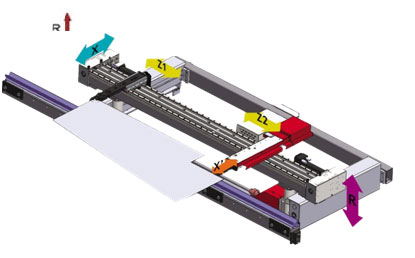

- Number of Axes: Modern CNC press brakes can have multiple axes of control (e.g., Y1, Y2 for ram movement, X, R, Z1, Z2 for back gauge positioning). A higher number of controlled axes allows for more complex bending operations and typically translates to a higher price due to the sophisticated control systems and mechanical components involved.

- Ram Stroke and Open Height: A larger ram stroke allows for deeper bends, while a greater open height accommodates taller tooling and parts. These increased capacities often correlate with a higher price.

Control Systems for Accurl Press Brake Price

The sophistication of the control system significantly impacts the price. Accurl offers various control options, ranging from basic NC (Numerical Control) systems to advanced CNC (Computer

- 2D or 3D Graphical Interfaces: These user-friendly interfaces simplify programming and simulation, often found on higher-priced models.

- Offline Programming Capabilities: Software that allows programming away from the machine can increase productivity but may add to the overall cost.

- Advanced Features: Functions like automatic crowning (to compensate for machine deflection), angle programming, and integration with other automation systems contribute to a higher price point.

- Automation and Accessories: The level of automation integrated with the press brake also affects the price. Options such as:

- Automated Back Gauge Systems: Precise and multi-axis back gauges enhance accuracy and speed, increasing the machine’s value.

- Material Handling Systems: Features like sheet followers or robotic integration can significantly boost productivity but add to the initial investment.

- Safety Systems: Advanced safety features, such as light curtains or laser safety devices, are crucial but can also influence the price.

- Brand Reputation and Quality: Accurl is a recognized manufacturer in the sheet metal industry. Their reputation for quality, reliability, and after-sales service can factor into the pricing compared to lesser-known brands.

Customization and Options: Buyers often require specific tooling, software configurations, or other customizations to suit their unique applications. These tailored solutions will naturally affect the final price.

Market Factors for Accurl Press Brake Price

External factors such as raw material costs, manufacturing processes, and global supply chain dynamics can also influence the pricing of Accurl press brakes over time.

General Price Range: Due to the wide array of models and configurations offered by Accurl, it’s difficult to provide a specific price range without knowing the exact specifications required. However, generally speaking, Accurl press brakes can range from entry-level machines suitable for simpler tasks at a more affordable price point to high-end, multi-axis CNC models with advanced automation capabilities that command a significantly higher investment.

Conclusion for Accurl Press Brake Price

Determining the price of an Accurl press brake necessitates a thorough evaluation of the required specifications, control system sophistication, automation needs, and any desired customizations. Potential buyers are advised to directly contact Accurl or their authorized dealers to discuss their specific requirements and obtain an accurate and comprehensive quotation. Understanding the factors outlined above will empower buyers to have more informed discussions and make a purchase that best meets their operational and budgetary needs.