Estun Robotics

Estun Robotics Leading the Industry

Estun’s commitment to innovation has made it a top player in the robotics field, with over 95% autonomy in core components. Offering a comprehensive range of industrial robots, Estun dominates the Chinese market, consistently leading domestic brands in shipments.

Estun Robots are at the forefront of the robotics revolution, offering cutting-edge robotic solutions that enhance automation across industries. With Estun Robotics leading the way, businesses can unlock new levels of efficiency, precision, and scalability in their production processes. Known for their robust performance and seamless integration, Estun robots are trusted by manufacturers worldwide to automate tasks like welding, cutting, assembly, and material handling. Whether you’re seeking advanced robotic automation for high-volume production or a versatile solution to streamline your operations, Estun robots deliver unmatched reliability. Discover the power of Estun automation and elevate your manufacturing capabilities to the next level with our innovative robotic solutions.

Request more information

Collaboration Estun Robotic Solutions

Revolutionary Technology: ESTUN specializes in advanced robots for processes such as stamping, bending, and high-protection die-casting, offering customized solutions that enhance product quality and boost competitiveness. From start to finish, ESTUN provides comprehensive solutions for the entire metalworking process, including automated core production, parts handling, welding, die-casting, drilling, milling, plate bending, and subsequent processing.

As leaders in robotics

As pioneers in robotics automation and Industry 4.0, we seamlessly integrate digital technologies with our robotic systems to deliver cutting-edge, high-quality solutions that transform manufacturing capabilities.”

Request more information

Trend of Automation and Intelligence in Industry

Fixed Machinery

No Interaction

Separated Space

Repetitive Work

Large Investment

Movable Machinery

Human-Robot Interaction

Shared Space

Adaptable to Switch Often

Flexible ROI

- Labor-intensive industries are turning to automation.

- Structured application scenarios are changing to unstructured scenarios.

- Orders are evolving to diversification and flexibilization

- Traditional interaction is changing to intelligent interaction

Request more information

Robot related applications

Complete solutions for robots in various industries

Focusing on the digital application needs of smart factories, Estun has comprehensively extended upwards to create a complete digital solution for the whole life cycle, and provide digital products and services in production line design, simulation and verification, integrated delivery, and smart factory operation and maintenance. Estun has built the E-Noesis cloud platform, which provides digital functions covering process quality inspection and optimization, fault early warning analysis, remote operation and maintenance, etc.

making equipment parameters, process parameters, production capacity and quality and other data transparent, and providing users with digital core

- Independent safe joint module

Certified safety controller - Active safety design

Independent dual-channel redundant sensors, monitoring position and force in real-time - Certified function safety, multiple protection features

ISO 13849-1 Cat.3 PLd

ISO 10218-1:2011(incl. ISO/TS 15066:2016) - Highly sensitive collision protection

Built-in torque sensors

No requirement on safety light curtains & fences

- Built-in high precision sensors

Enabled with force control package, easy to use - Hand guide is sensitive and flexible

and path teaching are more convenient and higher precision - Integrated high dynamic force control and vision

Support hand guide in axis/cartesian space.

Adaptable to unstructured and dynamic environments - Easy-to-use GUI programming

Combined with intuitive hand guide, the programing can be mastered in 1 hour by inexperience user. - Integrated vision and force control

Fulfill the requirements of automation in unstructured and dynamic environments

- Joint & End speed

Comparable to traditional industrial robots - High-precision Dynamic Model Identification and Compensation

Precise trajectory, more stable movement - Precision calibration and compensation techniques

Precision upgrades to industrial robot level

Repeat positioning accuracy <0.02mm - Unified force control and motion control framework

High-performance open control system

- Strict quality control & inspection

To ensure reliable product performance and quality - Kinematic accuracy calibration

The results of precision are stored in production system database to ensure absolute accuracy and traceability. - Production Quality Management System

ISO 9001 certification - Strict delivery inspection

100+ design type tests

20+ factory inspections

120 hours of continuous failure-free operation before leaving the factory

Mass Applications in Industries

Electronics

- Pick & Place

- Screw locking

- Visual assembly

- PCB welding

- Sophisticated assembly

- Packaging & palletizing

- Separator tearing and filming

- Dispensing and gluing

- Spraying

- Labeling

Automotive

- Engine assembly

- Window gluing

- Door press fitting

- Visual Inspection

- Grinding

- Product Traceability

- Battery Pack

Tightening

- Car Seat Tightening

- Mobile cobot for Materials

distribution

- Parts assembly

- Parts loading and unloading

Other Industries

- Metal processing – Machine tending

- Power – power line patrol, live-working

- New retail – coffee, milk tea, ice cream, pancake…

- Medical – surgery auxiliary, testing

- Food & Beverage – Palletizing

- Pharma – palletizing, loading and unloading, function

testing

- Glass Manufacturing – Grinding, handling

- Injection molding – loading and unloading

- Logistics & Warehousing – Handling & Palletizing

Technology

- Leading structure – built-in joint torque sensors

- Proven technologies of industry robot and core components transferred from Estun

Collaboration

- Coordination between industrial robot and cobot

- Unified platform

- Simple integration

- More flexible application development

Supply Chain

- Benefits of powerful Estun supply chain

- Cost

- Delivery

- Quality

Know What

- Based on Estun extensive experience in the industrial robotics , we are more likely to know what customers want exactly

Service

- Estun has a strong customer service team in the world to support our cobot customers.

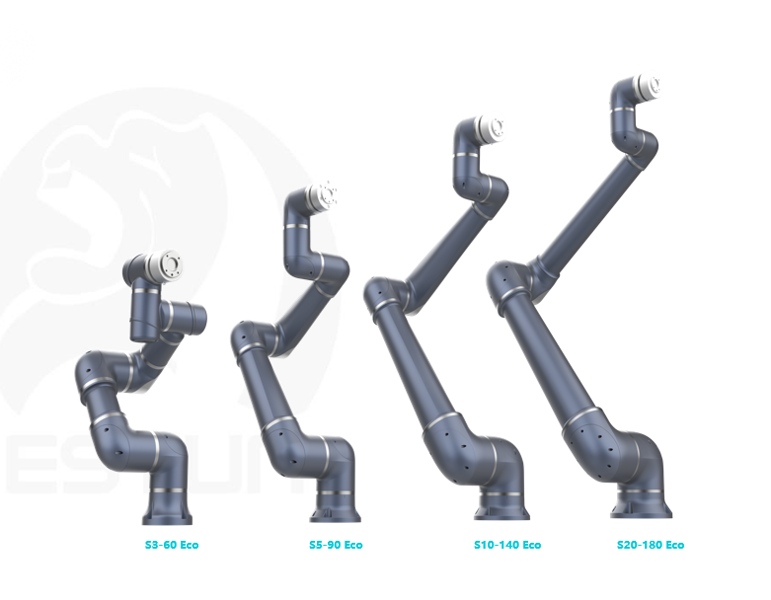

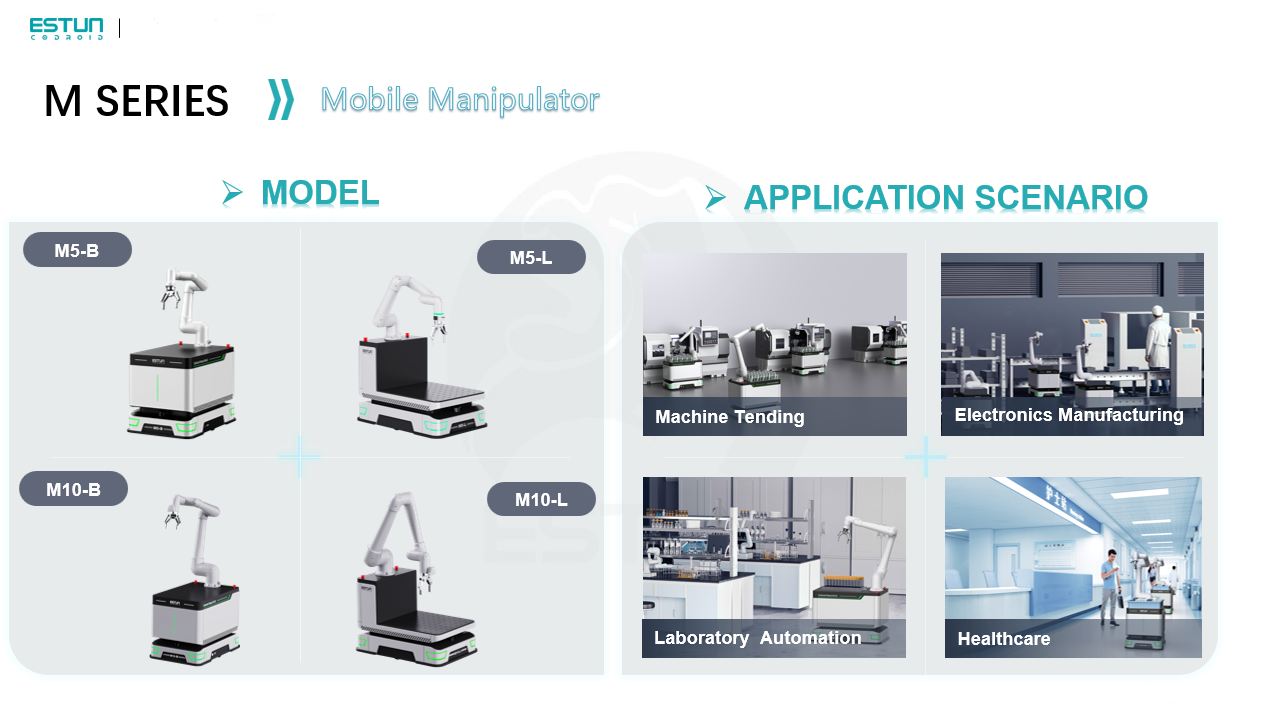

M SERIES » Mobile Manipulator

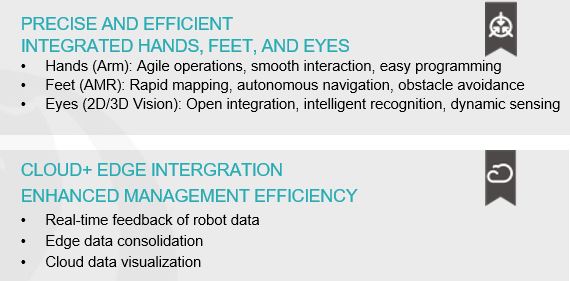

Equipped with cutting-edge laser SLAM and navigation technology, advanced visual sensing, and precise motion control, the M-series offers an integrated Hands-Feet-Eyes control system by combining collaborative robots (cobots) with Autonomous Mobile Robots (AMRs). With its intelligent environment recognition and precise route planning, the M-series ensures accurate and consistent operations while autonomously avoiding obstacles and people, enhancing both efficiency and safety in complex environments.

Get The Catalog

Download the full robotic arms catalog and explore all models, specifications, and integration options in one place.

Related products

Robotic Loading and Unloading for Fiber Laser Cutting

Material handling robots Robotic Loading & Unloading for Fiber Laser Cutting Fiber laser metal cutting

Welding and Cutting Robot

Metal welding and cutting robot Introduction Overview Features Applications Software Introduction Robotic 3D Laser Cutting

panel benders

panel benders and Robotic System Panel bending machine with robot and set upThe panel bender is a