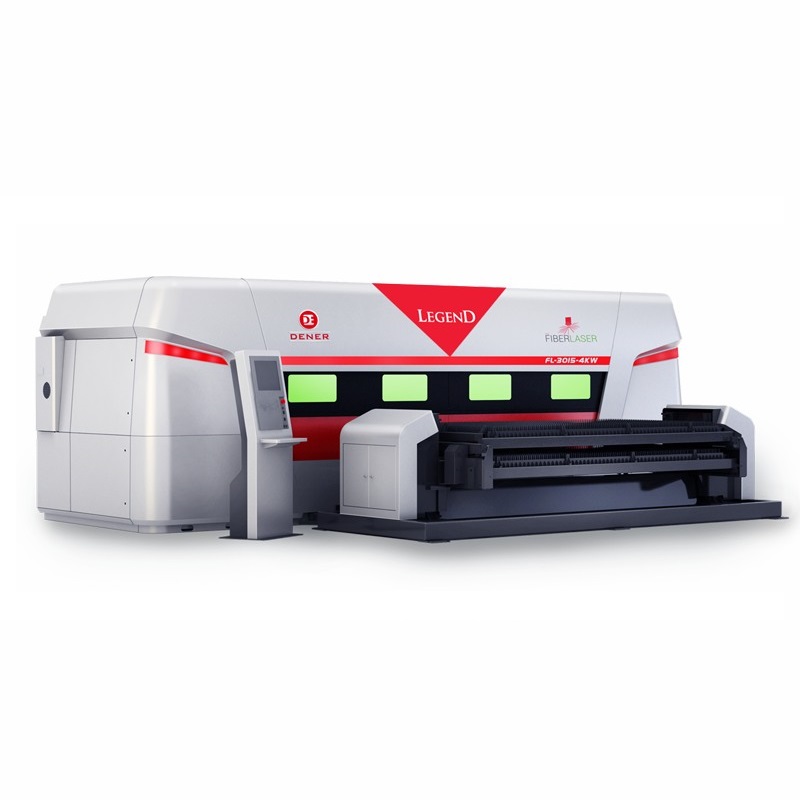

FL-3015-S

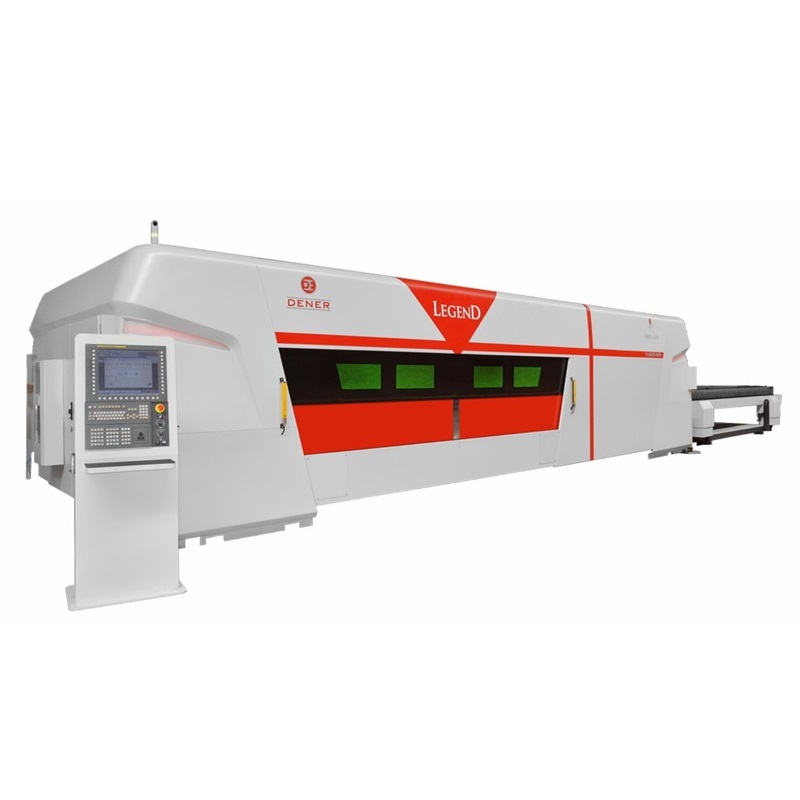

FL-4020-L

FL-6020-L

Full Automation in Laser Cutting Production Line by MegaMachineTurkey

At Mega Machine Turkey, we specialize in fully automating laser cutting production lines. Our advanced automation systems ensure that loading and unloading processes are carried out entirely without human intervention. By integrating cutting-edge robotic technology and smart sensors, we eliminate the need for manual labor, increasing efficiency, precision, and safety. With our state-of-the-art solutions, businesses can achieve higher productivity while reducing operational costs and minimizing errors.

| Model | Cutting Power | Max Cutting Size | Speed | Positioning Accuracy | Weight |

|---|---|---|---|---|---|

| FL-3015-S | 1-8kW | 1530x3050mm | 170m/min | 0.05mm | 16,000kg |

| FL-4020-L | 1-8kW | 2040x4050mm | 170m/min | 0.05mm | 21,500kg |

| FL-6020-L | 1-8kW | 2040x6050mm | 170m/min | 0.05mm | 26,000kg |

New Generation Fiber Laser Technology

- With autofocus system, thin and thick metal sheets can be cut with the best quality.

- One-piece welded body, capable of achieving a very high acceleration.

- Low operating cost and low energy consumption.

- Excellent cutting results on all types of material.

- High quality components recognized worldwide.

- Automatic sheet metal loading and unloading system.

- Modern and compact design.

- Dynamic structure and easy to use.

Get the catalog

Dener’s fiber laser cutting machines deliver unparalleled precision and energy efficiency. Featuring cutting-edge CNC control, automatic pallet changers, and innovative beam technology, our FL-Series machines ensure maximum productivity with minimal operational costs.

- Cutting Power: 1kW – 8kW

- Maximum Sheet Size: 1530x3050mm – 2040x6050mm

- Advanced CNC Control for Precise Cutting

- Efficient Energy Consumption – Up to 35% Savings

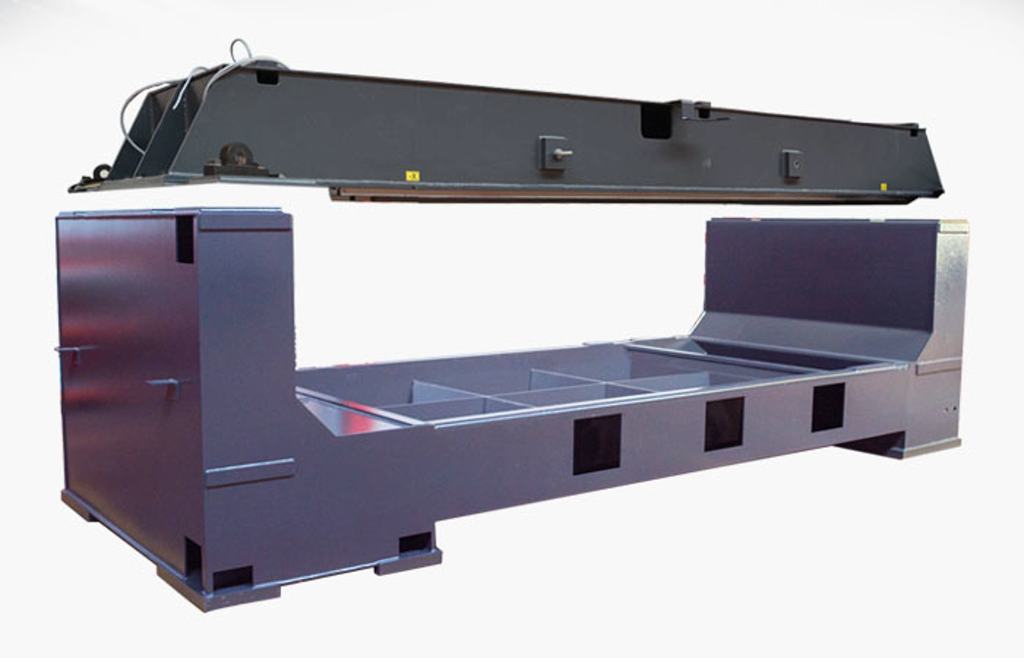

- Automatic Pallet Changer for Seamless Production

Fiber Laser Cutting Machines

Available laser power options: 4KW, 6KW, 8KW, 12KW, 15KW, 20KW, 30KW.

This machine features extremely low energy consumption and a very fast cutting capacity, along with minimal maintenance costs. It offers high productivity and superior quality standards. The chip collection system opens and closes based on the cutting head’s position, ensuring a clean work environment free from exhaust fumes or smoke. The toggle table system enhances workflow, simplifies material placement, and reduces part discharge time.

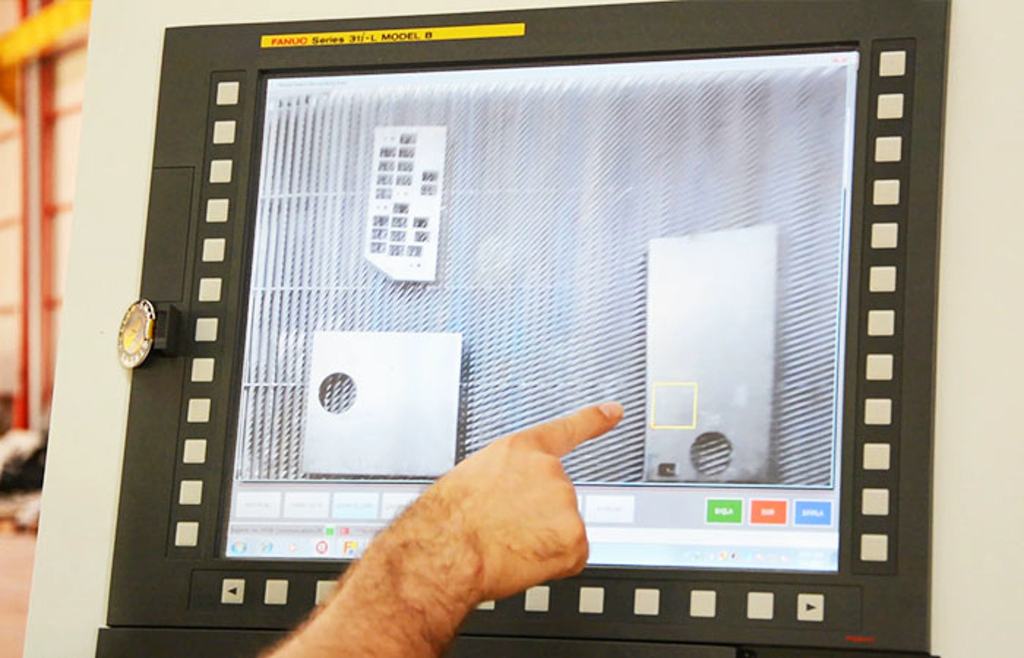

The plate’s angle and corner are automatically detected using a 3-point plate detection method. Fiber lasers are inherently designed for maintenance-free production, thanks to the diode’s exceptionally long lifespan of approximately 100,000 hours.

Request more information

Standard Equipments

• IPG resonator.

• 19″ LCD touch screen.

• Metalix software.

• Precitec cutting head.

• Shuttle table.

• Laser cooling system.

• Automatic gas selection system.

• Smoke suction filter.

• Air conditioner for automation panel.

• Slag car for the collection of cutting leftovers.

• Automatic sheet measurement vision system (Camera-based).

Optional Equipments

• Automatic beam centering system.

• Linear motor technology.

• Laser safety barrier.

• Piercing sensor.

• Automatic sheet metal loading and unloading system.

• Compressor.

DENER 6KW/4KW/2KW Fiber Laser Cutting Comparison

Request more information

Maximize efficiency with Dener’s cutting-edge fiber laser technology. Our FL-Series machines reduce operational costs, optimize energy consumption, and provide superior cutting accuracy across various materials.

✅ Energy Efficiency: Up to 35% lower power consumption than conventional systems.

✅ High-Speed Precision Cutting: Advanced servo motors and CNC technology ensure accuracy.

✅ Versatile Cutting Options: Capable of cutting steel, stainless steel, aluminum, copper, and brass.

✅ Automated Maintenance System: Self-lubrication & real-time monitoring for reduced downtime.

Why Choose Dener?

Established in 1974, Dener Makina is a global leader in sheet metal processing solutions. With over 50 years of expertise, ISO 9001 certification, and a presence in 80+ countries, we are committed to delivering cutting-edge laser cutting technology with world-class quality standards.

✅ 50+ Years of Industry Experience

✅ Advanced Fiber Laser Technology

✅ Global Presence in 80+ Countries

✅ ISO 9001 & European Safety Standards

✅ 24/7 Technical Support & Remote Monitoring

A laser cutting machine is a highly versatile and efficient tool used in various industries for precision cutting of materials. It utilizes a focused laser beam to create clean and accurate cuts on a wide range of materials, including metals, plastics, wood, and more. The laser beam melts, burns, or vaporizes the material, resulting in precise and intricate cuts with minimal heat-affected zones.

Laser cutting machines offer numerous advantages, such as high cutting speeds, excellent precision, and the ability to handle complex designs with ease. They are commonly used in manufacturing, automotive, aerospace, and architectural industries, among others.

These machines are equipped with advanced features like CNC (Computer Numerical Control) systems, allowing for automated and programmable operations. Additionally, they often come with software interfaces that enable easy design transfer and customization.

With their versatility and efficiency, laser cutting machines have revolutionized the manufacturing and fabrication processes, enabling faster production times and superior quality cuts. They have become an essential tool for businesses seeking precise and efficient cutting solutions.

Contact us

We’re here to help. Whether you have questions about our machines, need a custom solution, or want to become a partner, fill out the form below and our team will get back to you shortly.