laser cutting nozzle

How to choose the best nozzle for fiber laser cutting machine

- Laser nozzles are widely used and important parts in laser cutting machines that are placed close to the surface of the part.

- The nozzle emits a focused laser and high-pressure air flow, so the role of this part is very important and undeniable.

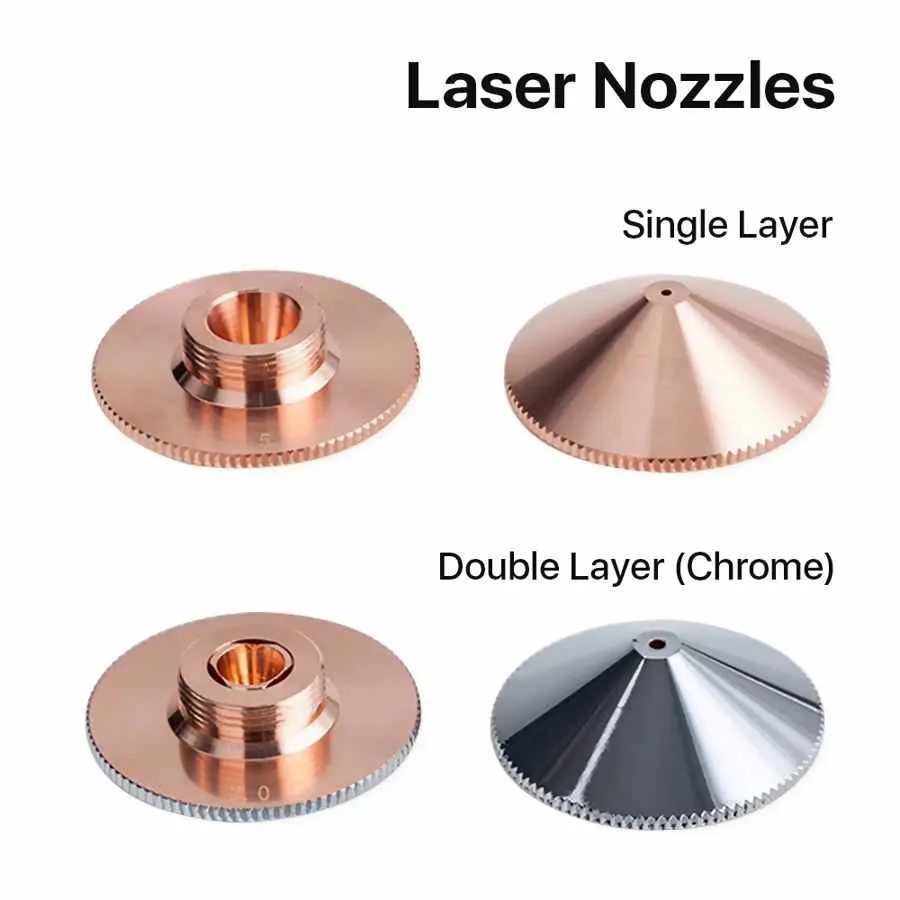

- Also, the fiber cutting nozzle (double nozzle and single nozzle) is able to give faster gas exit. It prevents the rise of waste and waste resulting from cutting, and as a result, it protects the laser focus lens (which is installed in the upper part of the nozzle).

- Another function of the nozzle is to control the gas pressure, which has a significant effect on the quality of the laser cutting machine.

What to look for when buying a LASER CUTTING NOZZLE machine?

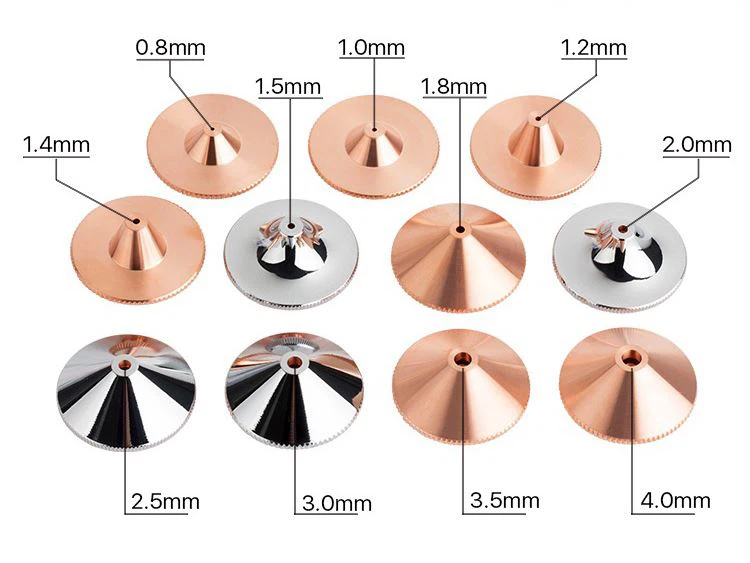

Laser nozzle size (oxygen nozzle and hydrogen nozzle):

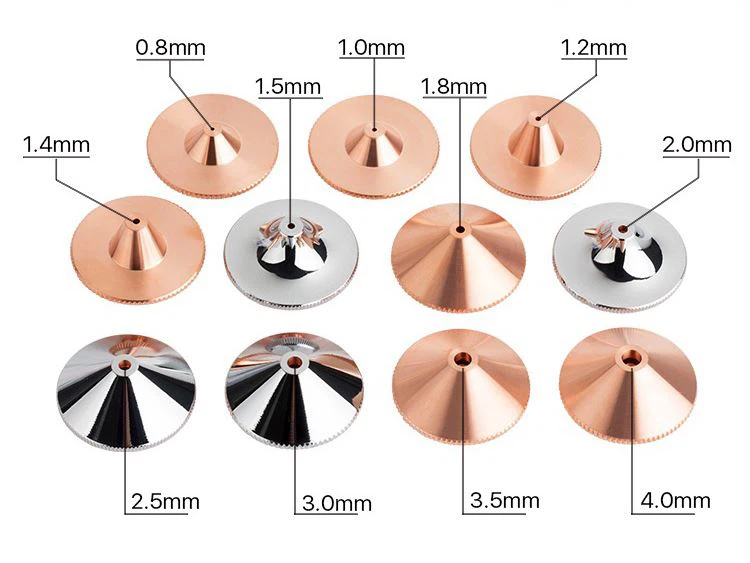

The size of the nozzle of the laser cutting machine (chrome coating nozzle) should be selected according to the thickness of the metal sheet to be cut.

The aperture of the laser head nozzle (original nozzle), which was selected from the beginning based on the thickness of the metal sheets, has the ability to control the flow and shape of the gas field, which is particularly important in improving the cutting quality.

The size of the diameter of the nozzle determines the size of the selected nozzle. Normally, for cutting sheets with a thickness of less than 3 mm, a nozzle with a diameter of 1 mm is used, and for cutting sheets with a thickness of more than 3 mm, nozzles with a diameter of 3.5 mm are used.

While generally, nozzles with a diameter of more than 2 mm are used to cut metal plates with a thickness of more than 10 mm.

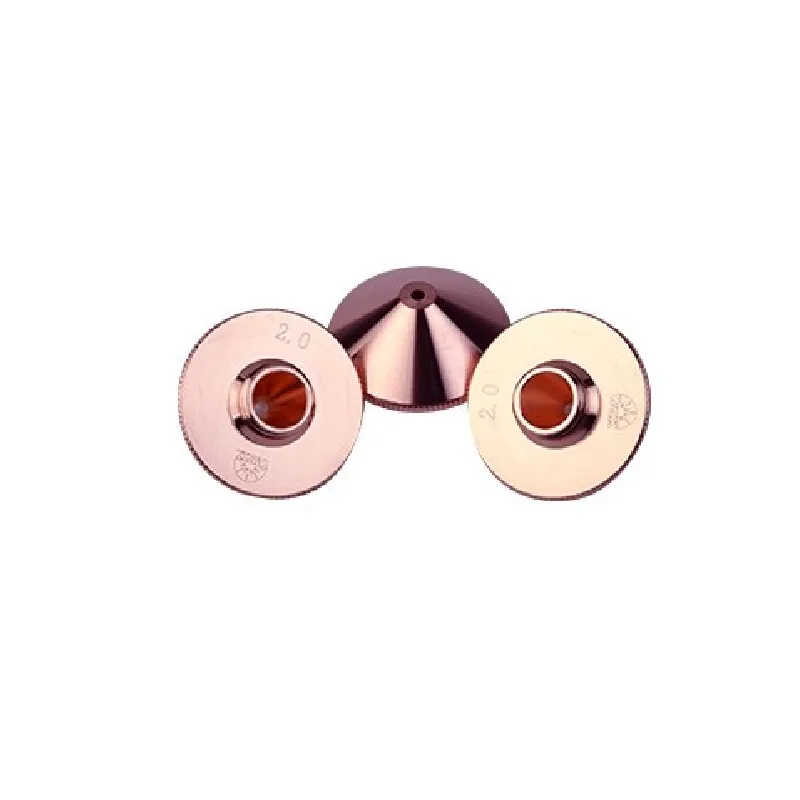

Material of laser cutting nozzle:

Regardless of the size, the ideal nozzle should also have the right material. For example, nozzles made of copper are more suitable than brass nozzles due to the greater guarantee of providing the capacitance signal.

In general, laser device nozzles must have high electrical and thermal conductivity.

Cutting machine nozzle processing accuracy:

A good laser nozzle should have an accuracy (dimensions) of 0.03 mm, and nozzles whose diameter is less than 1 mm should also have an accuracy (dimensions) of 0.02 mm.

Nozzles that have high precision can not only fix defects during laser operation, but also prevent the laser beam from returning to the cutting resonator device and as a result damage to the laser installed on the device.

The smooth surface of the nozzle and the anti-oxidation performance of the nozzle:

The smooth and polished surface of the nozzle can effectively reduce the adhesiveness of the molten material resulting from cutting and increase its useful life.

Fiber lazer kesim makinesi için en iyi nozul nasıl seçilir

- Lazer nozulları, lazer kesim makinelerinde yaygın olarak kullanılan ve parçanın yüzeyine yakın yerleştirilen önemli parçalardır.

- Nozul, odaklanmış bir lazer ve yüksek basınçlı hava akışı yayar, bu nedenle bu parçanın rolü çok önemli ve inkar edilemez.

- Ayrıca fiber kesim nozulu (çift nozul ve tek nozul) daha hızlı gaz çıkışı verebilmektedir. Kesimden kaynaklanan fire ve atıkların yükselmesini önler ve sonuç olarak lazer odak lensini (nozulun üst kısmına monte edilmiştir) korur.

- Nozulun bir diğer işlevi de lazer kesim makinesinin kalitesi üzerinde önemli bir etkiye sahip olan gaz basıncını kontrol etmektir.

Bir LAZER KESİM NOZULU makinesi satın alırken nelere dikkat edilmelidir?

Lazer nozul boyutu (oksijen nozulu ve hidrojen nozulu):

Lazer kesim makinesinin nozulunun (krom kaplama nozulu) boyutu, kesilecek metal sacın kalınlığına göre seçilmelidir.

Metal levhaların kalınlığına göre baştan seçilen lazer kafası nozulunun (orijinal nozul) açıklığı, gaz alanının akışını ve şeklini kontrol etme yeteneğine sahiptir ve bu özellikle kesim kalitesinin iyileştirilmesinde önemlidir.

Nozul çapının boyutu, seçilen nozulun boyutunu belirler. Normalde, kalınlığı 3 mm’den az olan levhaları kesmek için 1 mm çapında bir nozul kullanılır ve kalınlığı 3 mm’den fazla olan levhaları kesmek için 3,5 mm çapında nozullar kullanılır.

Kalınlığı 10 mm’den fazla olan metal plakaları kesmek için genellikle 2 mm’den fazla çapa sahip nozullar kullanılır.

Lazer kesim nozulunun malzemesi:

Boyuttan bağımsız olarak, ideal nozul da doğru malzemeye sahip olmalıdır. Örneğin, bakırdan yapılmış nozullar, kapasitans sinyalini sağlama garantisinin daha yüksek olması nedeniyle pirinç nozullardan daha uygundur.

Genel olarak, lazer cihazı nozulları yüksek elektriksel ve termal iletkenliğe sahip olmalıdır.

Kesme makinesi nozul işleme hassasiyeti:

İyi bir lazer nozulu 0,03 mm hassasiyete (boyutlara) sahip olmalıdır ve çapı 1 mm’den küçük olan nozullar da 0,02 mm hassasiyete (boyutlara) sahip olmalıdır.

Yüksek hassasiyete sahip nozullar sadece lazer çalışması sırasında kusurları düzeltmekle kalmaz, aynı zamanda lazer ışınının kesme rezonatör cihazına geri dönmesini ve sonuç olarak cihaza takılı lazerin hasar görmesini önler.

Nozulun pürüzsüz yüzeyi ve nozulun oksidasyon önleyici performansı:

Nozulun pürüzsüz ve cilalı yüzeyi, kesimden kaynaklanan erimiş malzemenin yapışkanlığını etkili bir şekilde azaltabilir ve kullanım ömrünü artırabilir.

How to choose the best nozzle for fiber laser cutting machine

- Laser nozzles are widely used and important parts in laser cutting machines that are placed close to the surface of the part.

- The nozzle emits a focused laser and high-pressure air flow, so the role of this part is very important and undeniable.

- Also, the fiber cutting nozzle (double nozzle and single nozzle) is able to give faster gas exit. It prevents the rise of waste and waste resulting from cutting, and as a result, it protects the laser focus lens (which is installed in the upper part of the nozzle).

- Another function of the nozzle is to control the gas pressure, which has a significant effect on the quality of the laser cutting machine.

What to look for when buying a LASER CUTTING NOZZLE machine?

Laser nozzle size (oxygen nozzle and hydrogen nozzle):

The size of the nozzle of the laser cutting machine (chrome coating nozzle) should be selected according to the thickness of the metal sheet to be cut.

The aperture of the laser head nozzle (original nozzle), which was selected from the beginning based on the thickness of the metal sheets, has the ability to control the flow and shape of the gas field, which is particularly important in improving the cutting quality.

The size of the diameter of the nozzle determines the size of the selected nozzle. Normally, for cutting sheets with a thickness of less than 3 mm, a nozzle with a diameter of 1 mm is used, and for cutting sheets with a thickness of more than 3 mm, nozzles with a diameter of 3.5 mm are used.

While generally, nozzles with a diameter of more than 2 mm are used to cut metal plates with a thickness of more than 10 mm.

Material of laser cutting nozzle:

Regardless of the size, the ideal nozzle should also have the right material. For example, nozzles made of copper are more suitable than brass nozzles due to the greater guarantee of providing the capacitance signal.

In general, laser device nozzles must have high electrical and thermal conductivity.

Cutting machine nozzle processing accuracy:

A good laser nozzle should have an accuracy (dimensions) of 0.03 mm, and nozzles whose diameter is less than 1 mm should also have an accuracy (dimensions) of 0.02 mm.

Nozzles that have high precision can not only fix defects during laser operation, but also prevent the laser beam from returning to the cutting resonator device and as a result damage to the laser installed on the device.

The smooth surface of the nozzle and the anti-oxidation performance of the nozzle:

The smooth and polished surface of the nozzle can effectively reduce the adhesiveness of the molten material resulting from cutting and increase its useful life.