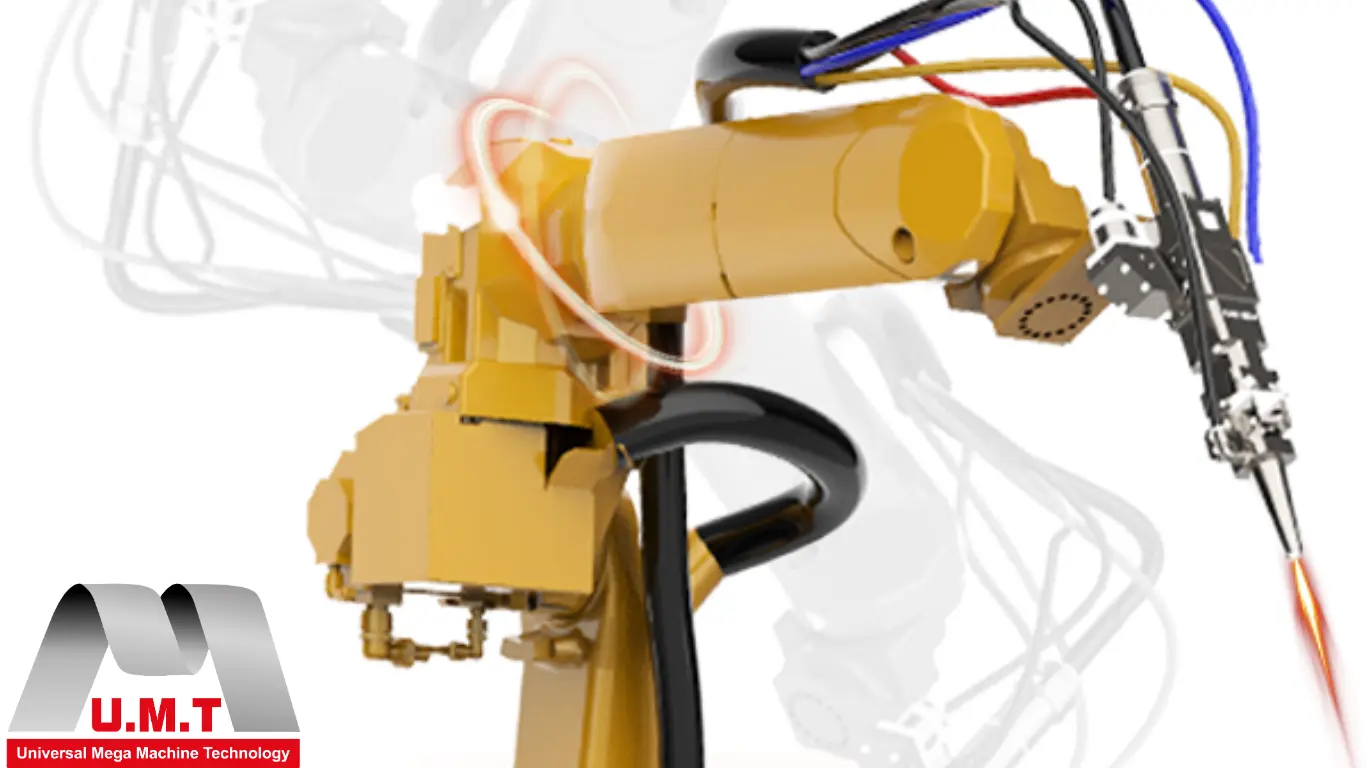

Robotic Welding In Dubai has emerged as a transformative technology in the manufacturing landscape, fundamentally altering how metal joining processes are executed. By integrating programmable robots with sophisticated welding equipment, this automation offers significant advantages over traditional manual welding, leading to enhanced efficiency, precision, and safety across various industries.

At its core, Robotic Welding In Dubai involves the use of automated robotic arms equipped with welding torches or other welding tools. These robots are programmed to follow precise paths and parameters, ensuring consistent and high-quality welds. The technology encompasses various welding processes, including arc welding (GMAW, GTAW, FCAW), spot welding, and laser welding, each offering unique benefits for different applications and materials.

The adoption of Robotic Welding In Dubai is driven by a multitude of factors. Firstly, it significantly increases productivity and throughput. Robots can operate continuously without fatigue, leading to faster cycle times and higher production rates compared to manual welders. Secondly, robotic systems deliver superior weld quality and repeatability. Their precise movements and consistent application of welding parameters minimize errors and defects, resulting in stronger and more reliable joints. This consistency is particularly crucial in industries with stringent quality standards, such as automotive and aerospace.

Application of Robotic Welding In Dubai in our workplace

Furthermore, robotic welding enhances workplace safety. Welding environments can be hazardous due to heat, fumes, and potential for injury. By automating the welding process, human workers are removed from these dangerous conditions, leading to a safer and healthier work environment. This also contributes to reduced healthcare costs and improved employee morale.

The flexibility of robotic welding systems is another key advantage. Robots can be reprogrammed to handle different welding tasks and complex geometries with relative ease, making them adaptable to varying production needs and product designs. This flexibility is further enhanced by advancements in sensor technology and artificial intelligence, allowing robots to perform more complex tasks and even adapt to real-time variations.

FOR VIEW MORE ROBOTS OF MEGAMACHINE CLICK HERE!!!!

While the initial investment in Robotic Welding In Dubai systems can be substantial, the long-term benefits often outweigh the costs. Reduced labor costs, decreased material waste due to fewer defects, and increased production efficiency contribute to a significant return on investment. As technology continues to advance and become more accessible, robotic welding is poised to become an even more integral part of modern manufacturing, driving innovation and competitiveness across industries worldwide.